- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

The Critical Role of Surge Protective Devices (SPDs) in PV Combiner Boxes: Selection Guide and Best Practices

2025-06-23

Introduction: The Vulnerable Core of PV Arrays

PV combiner boxes serve as the nervous system of solar power plants, collecting multiple DC string outputs before feeding them into inverters. These critical nodes are constantly exposed to threats from lightning strikes and electrical surges that can cripple entire PV systems. High-quality surge protective devices (SPDs) act as the first line of defense, safeguarding equipment worth hundreds of thousands of dollars.

Chapter 1: Why SPDs Are Essential for PV Systems

1.1 Unique Vulnerabilities of PV Arrays

Constant Exposure: Rooftop and ground-mounted systems are naturally exposed to atmospheric discharges.

DC Circuit Risks: Unlike AC systems, DC arcs lack natural zero-crossing points, making surge events more hazardous.

Sensitive Electronics: Components in modern inverters can be damaged by voltages just 20% above the rated value.

1.2 Consequences of Inadequate Protection

Immediate Damage: 72% of inverter failures can be traced back to voltage surges (SolarEdge 2023 Report).

Hidden Degradation: Repeated minor surges can reduce module lifespan by up to 30%.

Fire Risks: DC arc faults account for 43% of solar-related fires (NFPA 2022 Data).

Chapter 2: Key Considerations for SPD Selection in PV Applications

2.1 Critical Performance Parameters

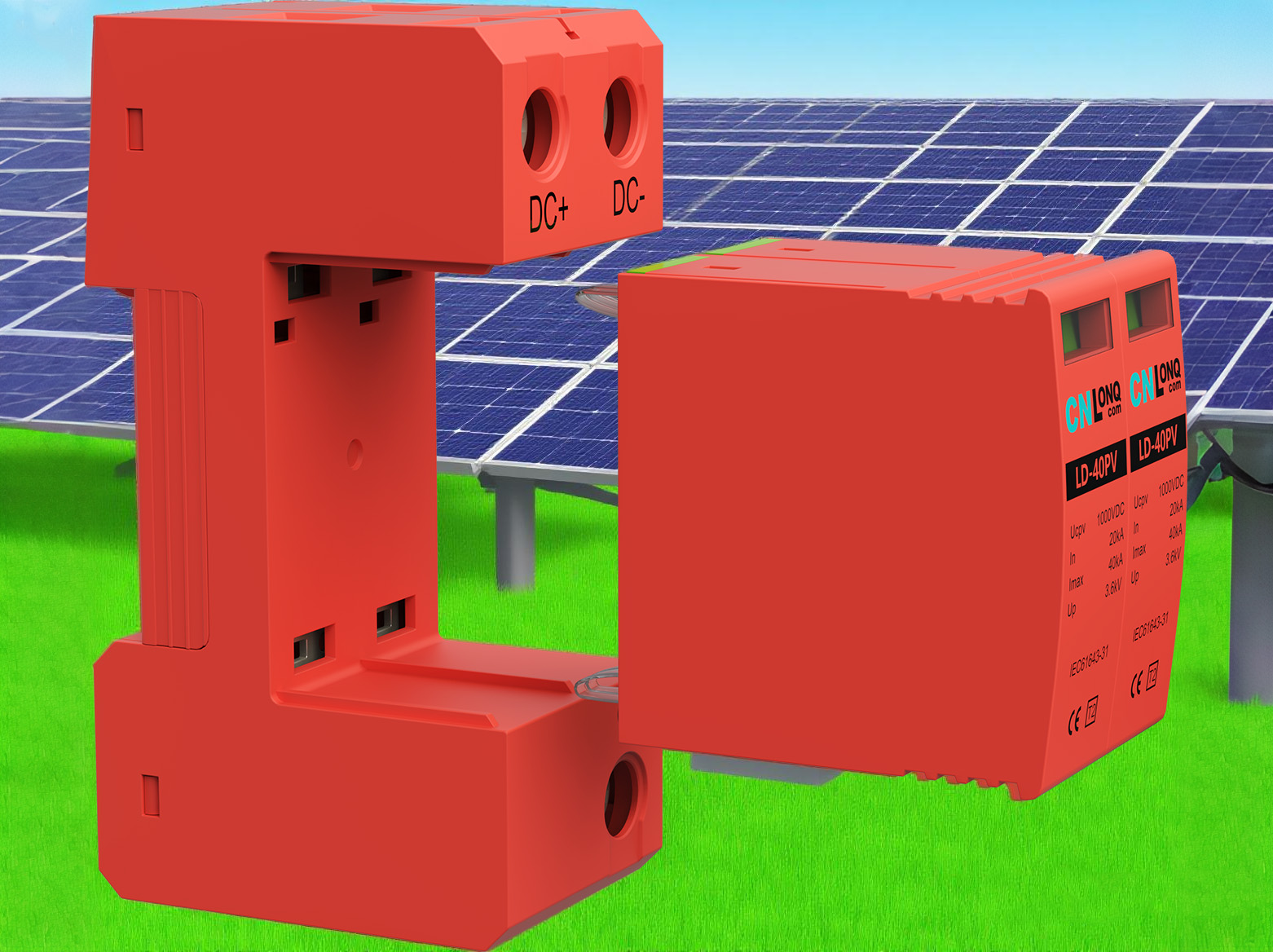

Rated Voltage: ≥1.2 times the system’s maximum voltage (per IEC 61643-31).

Nominal Discharge Current (In): ≥20kA for Type 1 SPDs (per UL 1449, 4th Edition).

Maximum Discharge Current (Imax): ≥40kA (per IEC 61643-11).

Response Time: <25 nanoseconds (per EN 50539-11).

Operating Temperature: -40°C to +85°C (per UL 96A).

2.2 SPD Types for Different Applications

Type 1 (Class I): For locations with direct lightning strike risks (e.g., rooftop systems).

Type 2 (Class II): For secondary protection (e.g., commercial ground-mounted systems).

Combined Type 1+2: Ideal for large utility-scale plants.

DC-Specific Models: Designed for PV applications with polarity markings.

Chapter 3: Best Practices for Installation

3.1 Strategic Placement

Mandatory Installation Points:

Combiner box input terminals (per string).

Upstream of DC disconnects.

Inverter DC input terminals.

Recommended Additional Protection Points:

Sub-array combiners.

Along long cable runs (>30 meters).

3.2 Wiring Standards

Conductor Size: Minimum 6 mm² copper (for 20kA SPDs).

Path Length: Keep SPD connections <0.5 meters.

Grounding Requirements: Use dedicated grounding conductors (≥10 mm²).

Connection Topology: Star configuration to avoid ground loops.

Chapter 4: Maintenance and Replacement Criteria

4.1 Preventive Maintenance

Quarterly Checks:

Inspect status indicator windows (green/red).

Perform infrared thermography (temperature rise <15K).

Record lightning strike counters (if equipped).

Annual Tests:

Insulation resistance test (>1 MΩ).

Ground resistance measurement (<10 Ω).

Residual voltage test by professionals.

4.2 Replacement Guidelines

Immediate Replacement Triggers:

Visible physical damage (cracks, burn marks).

Status indicator turns red.

Lightning strike count exceeds rated value.

Failed performance tests.

Recommended Replacement Intervals:

Coastal areas: 5 years.

High-lightning zones: 7 years.

Standard regions: 10 years.

Chapter 5: Common Misconceptions and Expert Recommendations

5.1 Typical Misunderstandings

Myth: "Lightning rods eliminate the need for SPDs."

Fact: Lightning rods only protect against direct strikes, not induced surges.

Cost Trap: Using non-PV-specific AC SPDs.

Consequence: Inability to interrupt DC follow currents.

5.2 Expert Advice

Adopt a three-tier protection architecture: SPDs at the array, combiner box, and inverter levels.

Choose models with remote signaling contacts for integration with monitoring systems.

For 1500V systems, verify the SPD’s DC breaking capacity.

Re-evaluate existing SPD capacity during system expansions.

As PV system voltages rise to 1500V, next-generation SPD technology is evolving with three key trends: higher energy absorption (up to 100kA), smarter warning features (IoT-enabled monitoring), and more compact modular designs. Selecting products certified by TUV Rheinland for PV applications and following IEC 62305 standards for system-level protection ensures PV plants can withstand lightning surges throughout their 25-year lifespan. Remember: In PV safety, high-quality surge protection isn’t an expense—it’s the most cost-effective risk mitigation investment.